- Home

- About Us

- Products

Mining & Construction Wear Parts

Ground Engaging Tools

Wear Linings

Conveyor Products

Undercarriage

Aggregate & Process Equipment

Rubber Tracks

Street Sweeping

(SNIC) Snow and Ice Control

- Special and News

- Policy

- Contact Us

Crushers

TRIO JAW CRUSHERS CT SERIES

| Design Feature | Benefit | Applications |

|---|---|---|

| Heavy-duty frame | Greater durability | Primary crushing applications in mining, aggregates, industrial minerals, and recycling concrete and asphalt |

| Long crushing chamber | Increased capacity | |

| Hydraulic adjustment | Easy adjustment of setting | |

| Heavy duty manganese or alloy jaw dies | Less frequent maintenance | Feed size preparation for conveying, primary milling or secondary crushing |

| Bolted construction | Allows for easy transport and accommodates underground installation | Mobile mounting on wheeled or track chassis |

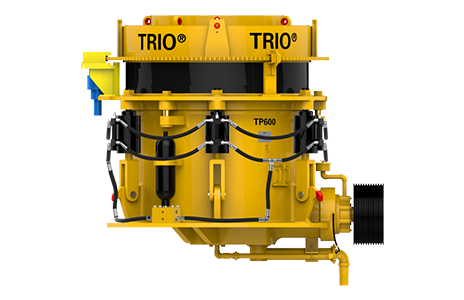

TRIO CONE CRUSHER TP SERIES

| Design Feature | Benefit | Applications |

|---|---|---|

| Compact design | Easy retrofit or replacement of lower performing crushers | Secondary, tertiary or quaternary stage crushing circuits |

| Counterweights | Reduces unbalanced forces and moments for increased mobility or placing on existing foundations | Specification size and/or shape classification for aggregate crushing |

| Spiral bevel gears | Reduced gear noise and longer gear life | Crushing ore for direct reduction, leaching or milling operations |

| Hydraulic adjustment | Easy adjustment of Closed Side Setting (CSS) | |

| Hydraulic tramp release | Prevents interruption of operation due to uncrushable materials | |

| Hydraulic clearing | Allows for safe clearing of crusher chamber in the event of crusher stall under load |

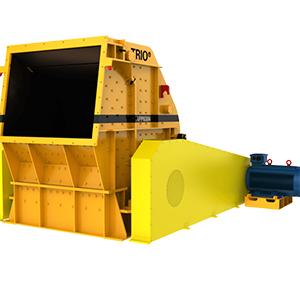

TRIO HSI CRUSHERS APP & APS SERIES

| Design Feature | Benefit | Applications |

|---|---|---|

| Heavy mass | Greater durability for frequent overload conditions | Secondary and tertiary stage crushing circuits |

| Tapered sleeve bearings | Well proven design for cone crushers | Specification size and/or shape classification for aggregate crushing |

| Spiral bevel gears | Reduced gear noise and longer gear life | Crushing ore for leaching or milling operations |

| Hydraulic adjustment | Easy adjustment of Closed Side Setting (CSS) | |

| Hydraulic tramp release | Prevents interruption of operation due to uncrushable materials | |

| Hydraulic clearing | Allows for safe clearing of crusher chamber in the event of crusher stall under load |

TRIO VSI CRUSHERS TV SERIES

| Design Feature | Benefit | Applications |

|---|---|---|

| Oversized feed hopper | Allows for easier feed conveyor placement | Fractured gravel |

| Hydraulic lid opening | Provides easy access into the crusher for inspection | Manufactured sand |

| Externally adjusted feed tube | Allows for the adjustment of the feed tube without opening the crusher | • Precious metals recovery |

| Air transfer system | Reduces dust emission | Re-crush of slow selling inventory |

| Adjustable and flexible crushing chamber options including Steel on Steel (SOS), Rock on Steel (ROS), and Rock on Rock (ROR) | Provides maximum application flexibility | Crushing and grinding of man-made materials for industrial abrasives |

| Oil lubrication with oil flow meter protection, oil heating and cooling with shut-down protection | Provides excellent performance and protects the bearing assembly |

Need Replacement Parts?

Keep your vehicles and equipment running smoothly.

Hanwell Branch

Visit us

Give us a call

Send us a message

Truro Branch

Visit us

Give us a call

Tel: 902-895-4913

© 2024 LSW Wear Parts Ltd. All rights reserved